Area of Expertise Worth Mentioning

Overview

Rockman is into the business of manufacturing Bicycle Chains since 1960. Rockman was one of India’s first company to develop Indigenous technology for manufacturing chains for bicycles. Soon Rockman started exports globally and became World’s Largest Producer for Bicycle Chains and Hubs.

Since the late 1990’s Rockman started manufacturing Two-Wheeler Drive and Cam Chains with initial technology transfer from Izumi, Japan for cam chains. Over the years, Rockman has developed in-house capabilities for development of toolings, special purpose machines, assembly lines for the chains. Cam chains which are critical for engine performance are produced in dust-free enclosures to ensure direct use in the assembly line of OEMs without the need of cleaning.

Infrastructure & Capacity – One dedicated plant at Mangli, Ludhiana for manufacturing chains with a capacity of 60,000 meter per day.

R & D development

Research & Development Lab

- ROCKMAN has a highly qualified and experienced team, having a full-fledged capability in designing and developing Chains & Sprockets of automobiles.

- Rockman R&D regularly evaluates products for quality levels and benchmarking, comparing with Indian and international chain manufacturers.

- Also, it incorporates the latest testing equipment competing among chain manufacturers.

- Chain component life is increased by heat control treatment and material design.

- Continuous testing and quality audits.

R & D Lab has following facilities

- Endurance Testing

- Universal Testing Machine

- Starter Chain Durability Test

- Millipore

- Chain Twist Checking

- Chain Length Checking

- Chain Bow Checking

- Rockwell Hardness Tester

- Bench Center

- Fatigue Testing Machine

Metallurgy Lab

Heat Treatment

Unlike other chain manufacturers , Rockman has world class Continuous Hardening & Tempering Furnaces to achieve stringent surface and core hardness of all components. Through hardening process, ensures plate endurance and strength is fully optimized & consistent.

Pin, Bush, Roller – Case Carbo nitriding Process ensuring surface hardness for high wear resistance and tough core hardness for better impact resistance, it also resist’s shock loadings

Metallurgy Lab

Rockman has advanced state of the art metallurgical lab equipped with following equipments to delivery high quality long lasting components to end user:

- Micro Hardness tester

- Metallurgical Microscope

- Stereo Zoom Microscope

- Vickers Hardness Tester

- Rockwell Hardness Tester

- Polishing Machine

- Belt Grinder

- Micro Cutting Machine

Tool Room

Rockman Industries has a state of the art in house precision Tool & Die manufacturing facility comprising of next generation CNC milling machine and high speed milling machines.

Tool Room has following facilities:

- VMC

- Wire cut EDM

- Jig Boring

- Shaper machine

- Grinding machine

- Burr removing machine

- Profile Grinder

- Lathe machine

Products

Drive Chains

420 DRIVE CHAIN

428 DRIVE CHAIN

428 H DRIVE CHAIN

1595 O RING DRIVE CHAIN

520 O-RING DRIVE CHAIN

520 Drive Chain

1595 Drive Chain

Cam Chains

SOLID BUSH CAM CHAIN

25HS CAM CHAIN

25H CAM CHAIN

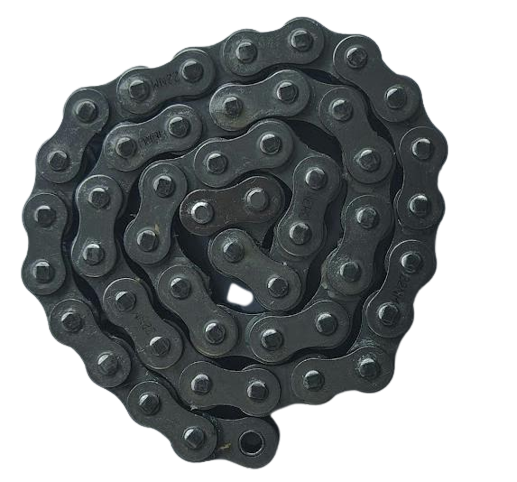

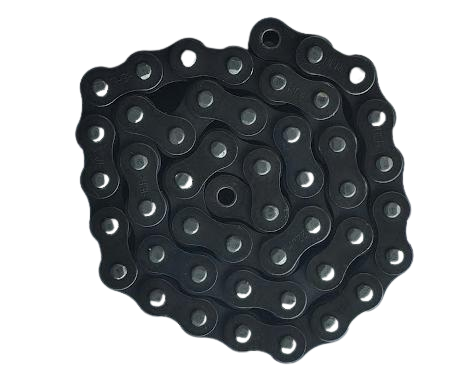

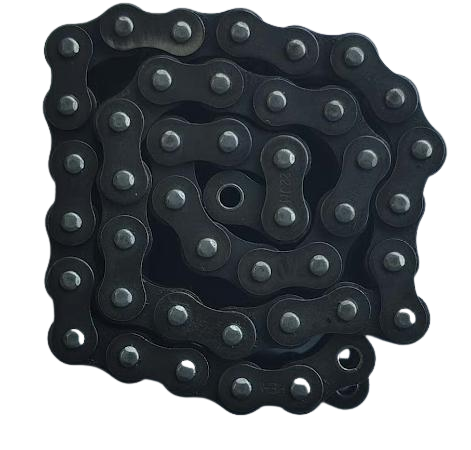

Industrial Chains

08B Chain

08B Chain

10B Chain

10B Chain

12B Chain

12B Chain

08B DUPLEX Chain

08B DUPLEX Chain

08B Triplex Chain

08B Triplex Chain

8B K2 Attachment Chain

![]()

08B DUPLEX Chain

08B Extruded pin Chain

08B Extruded pin Chain