Expertise Into All Casting Processes

Overview

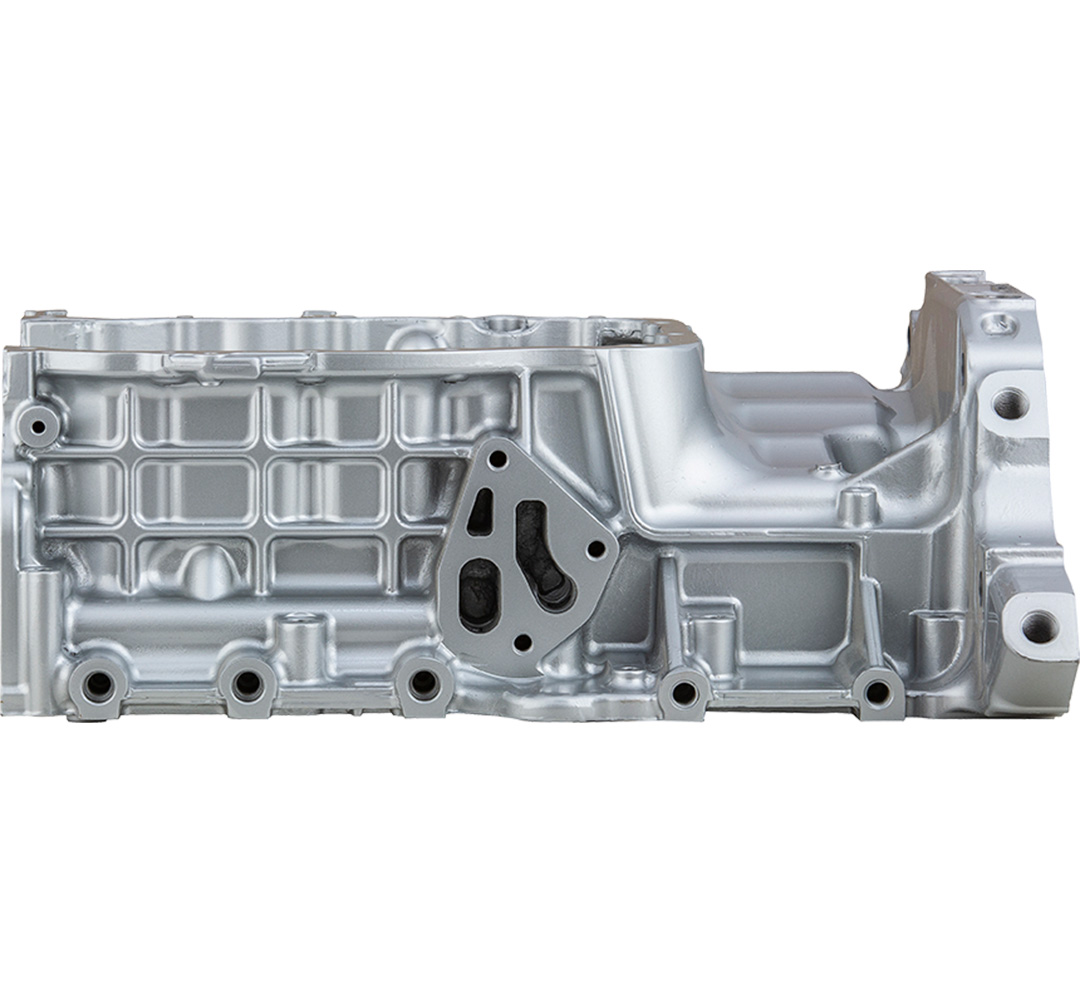

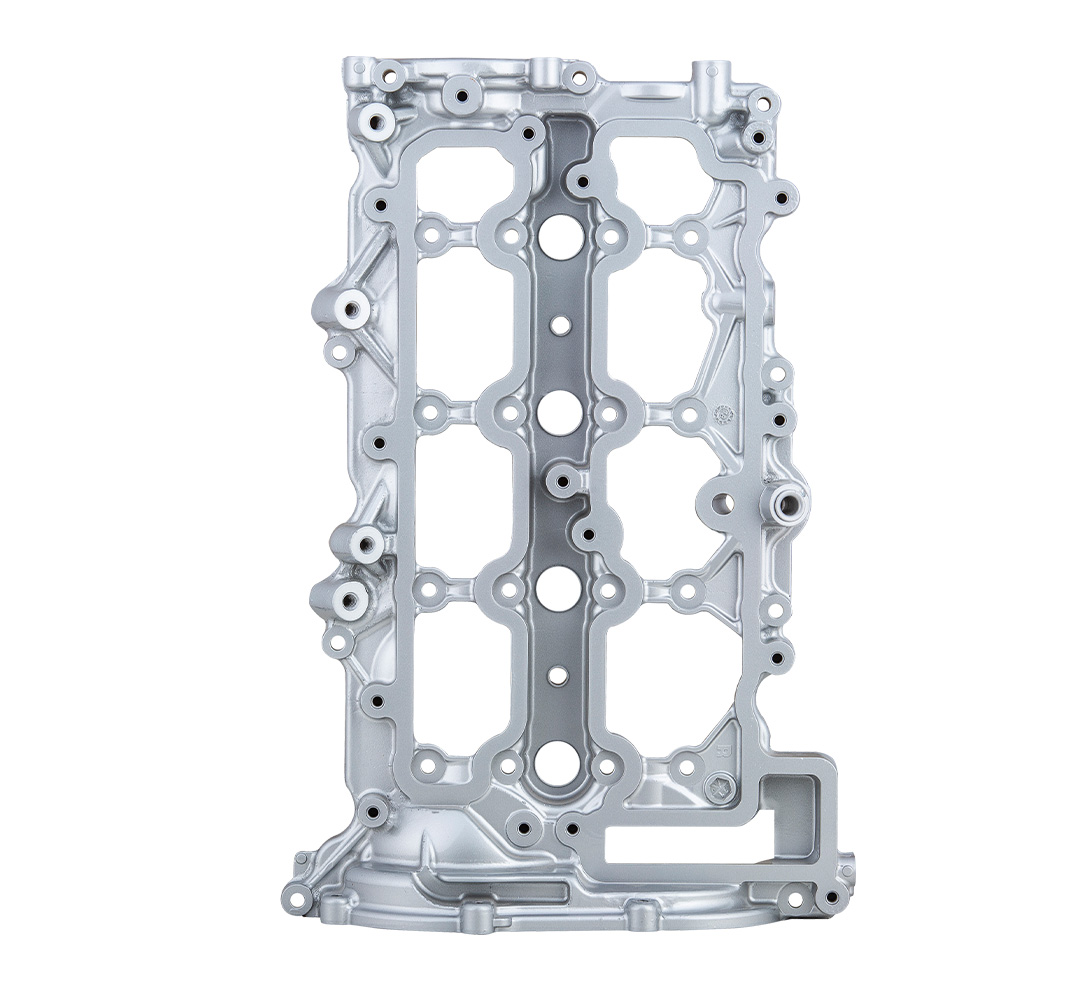

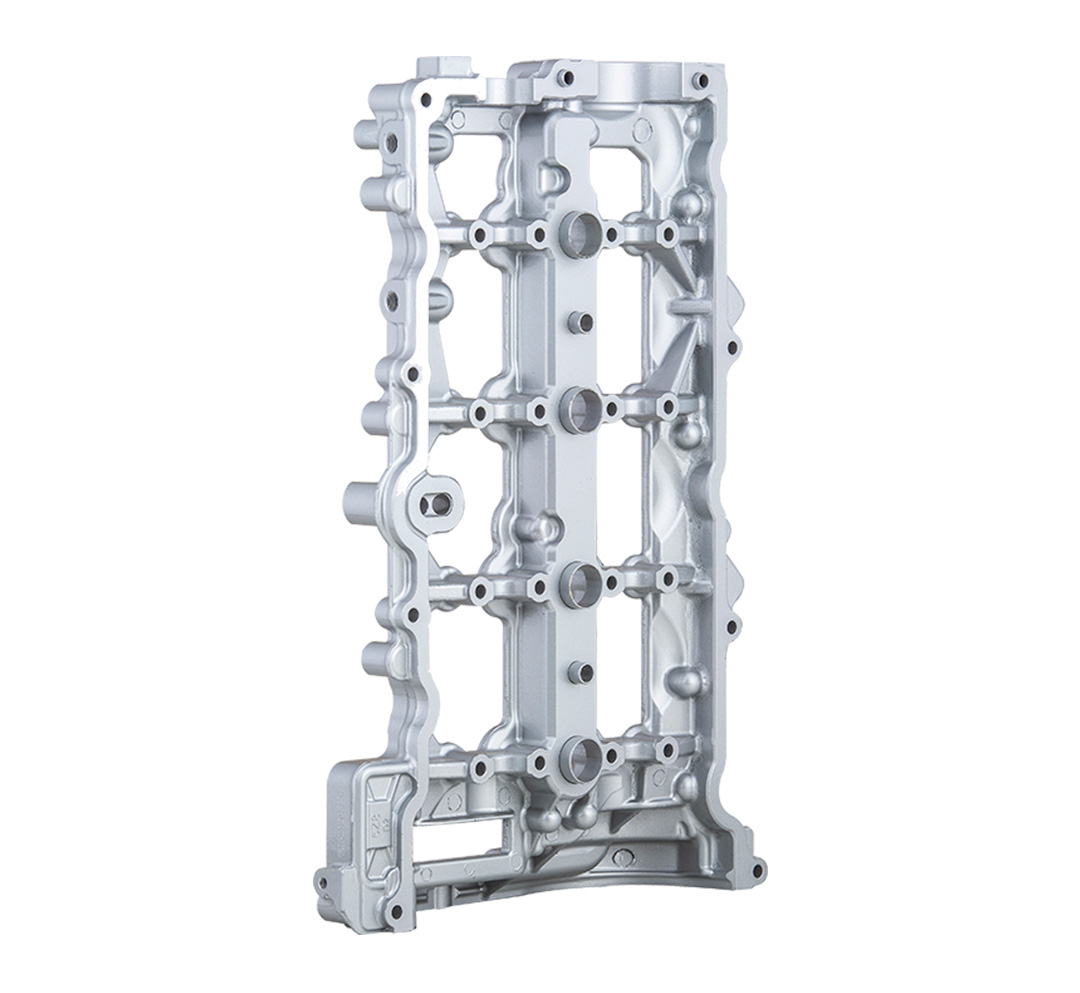

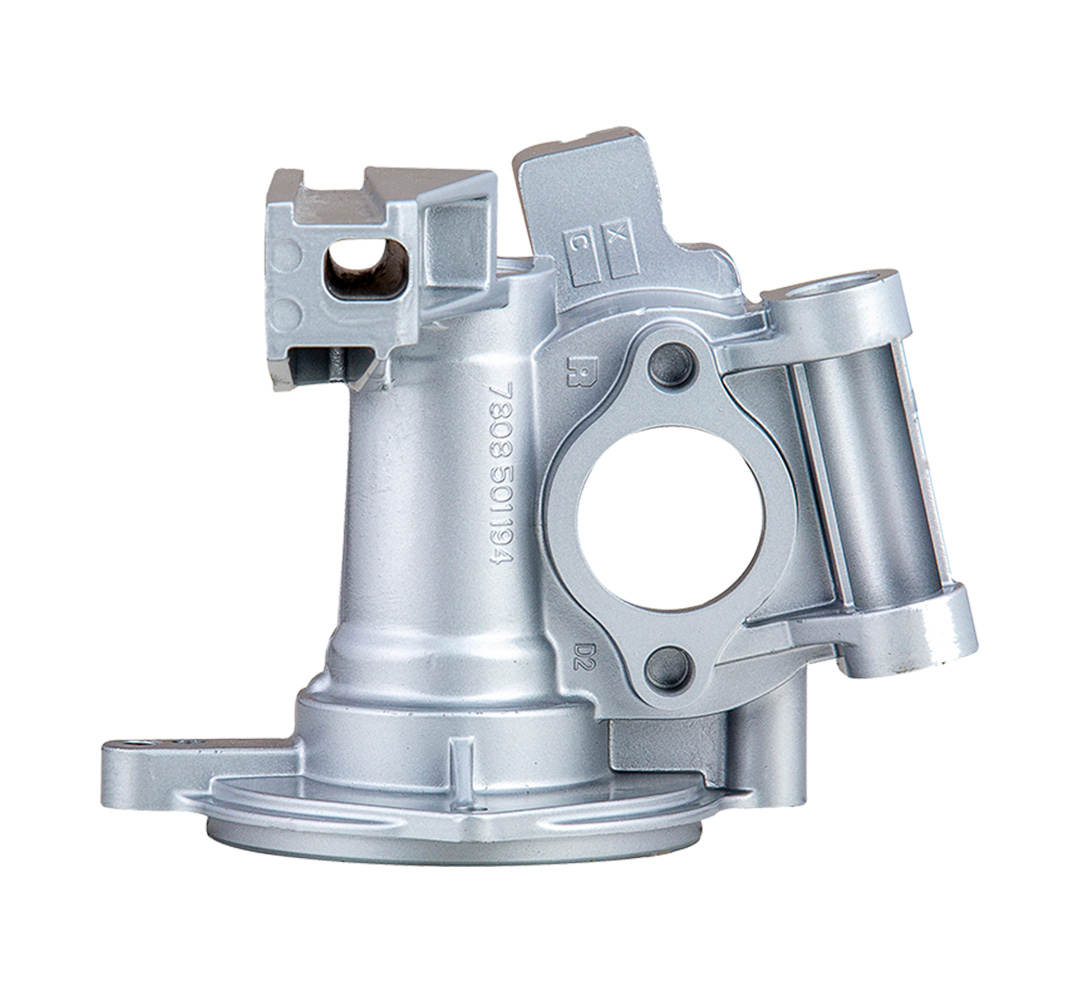

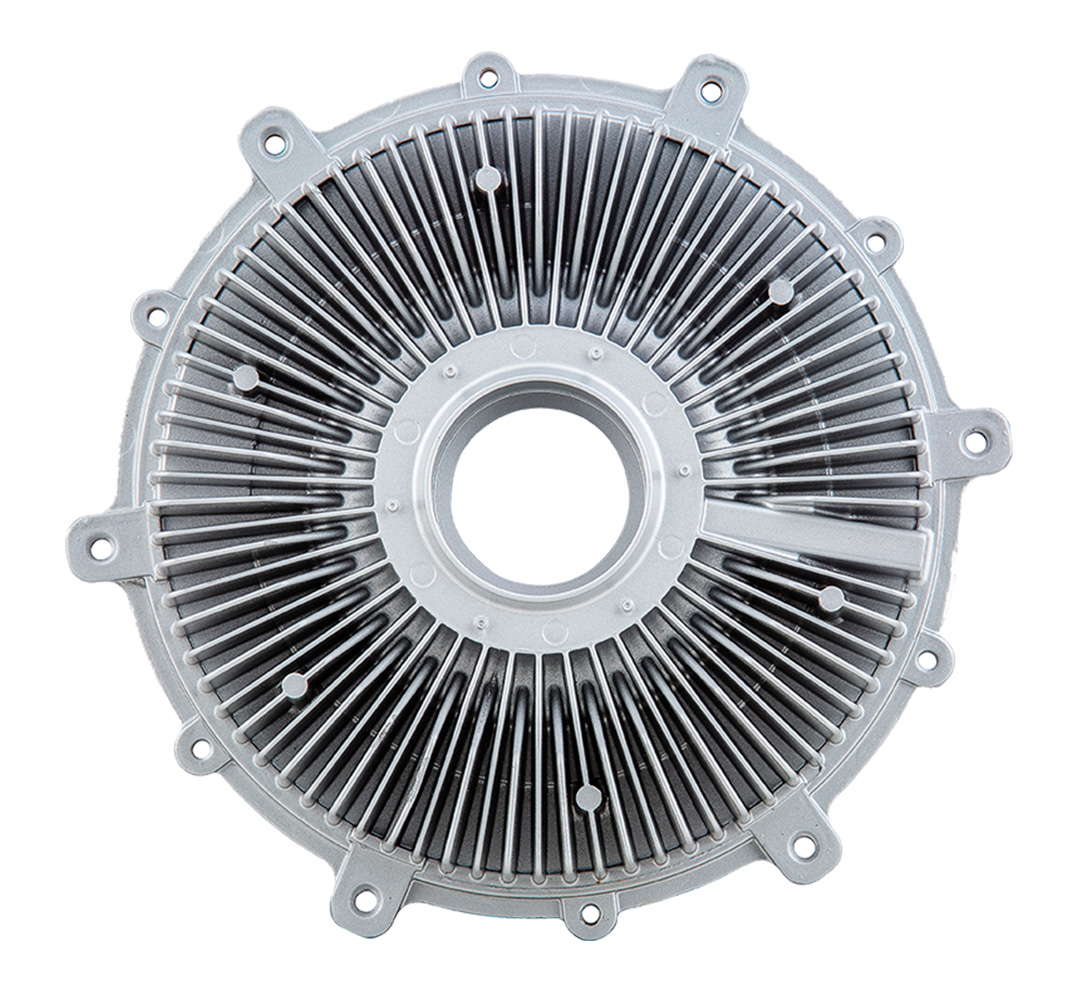

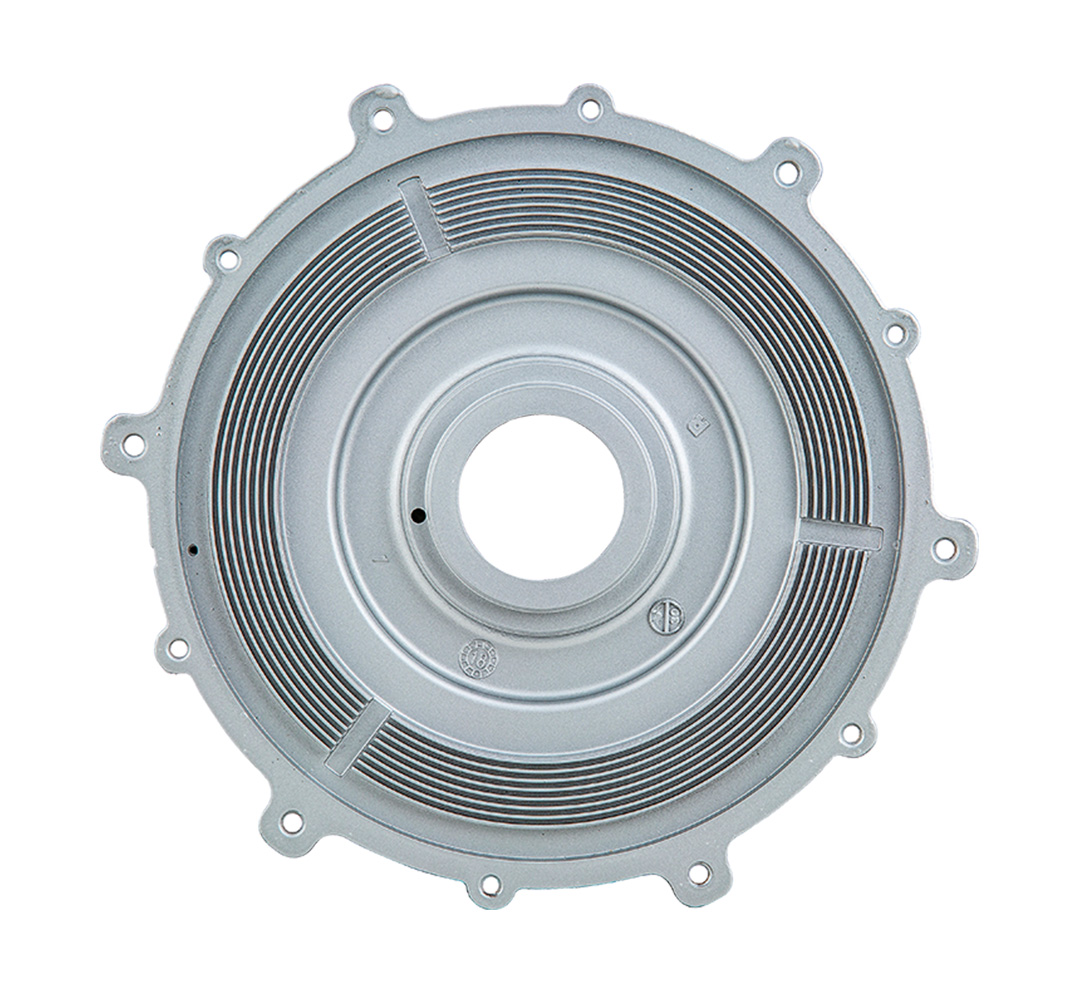

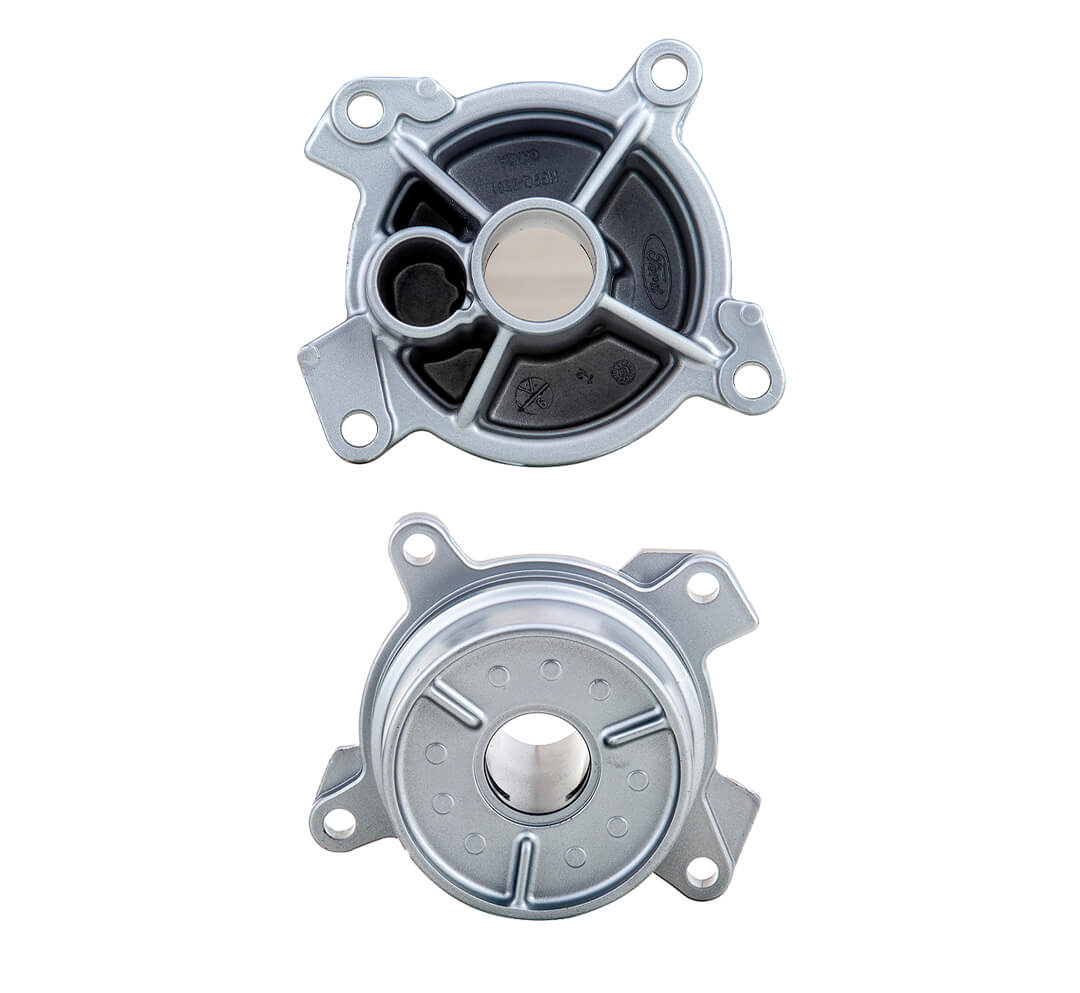

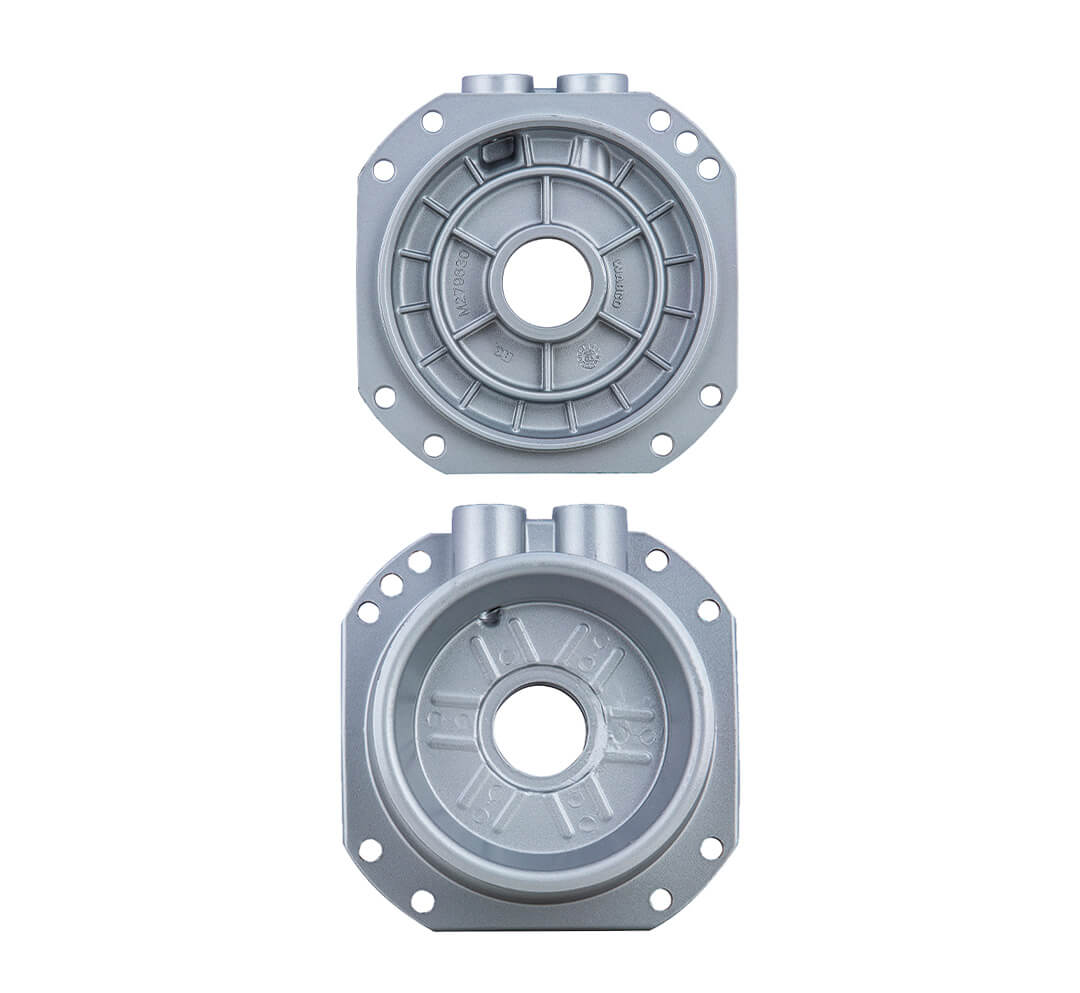

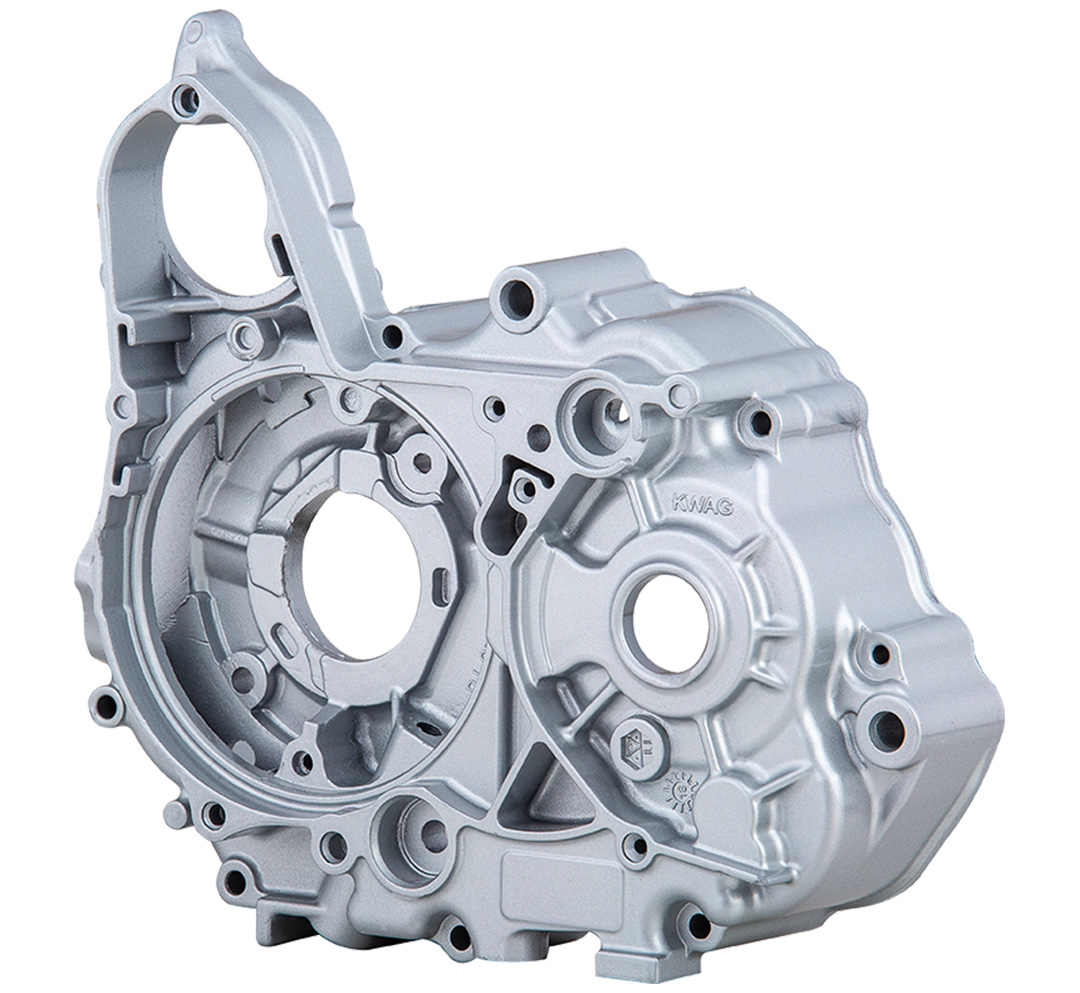

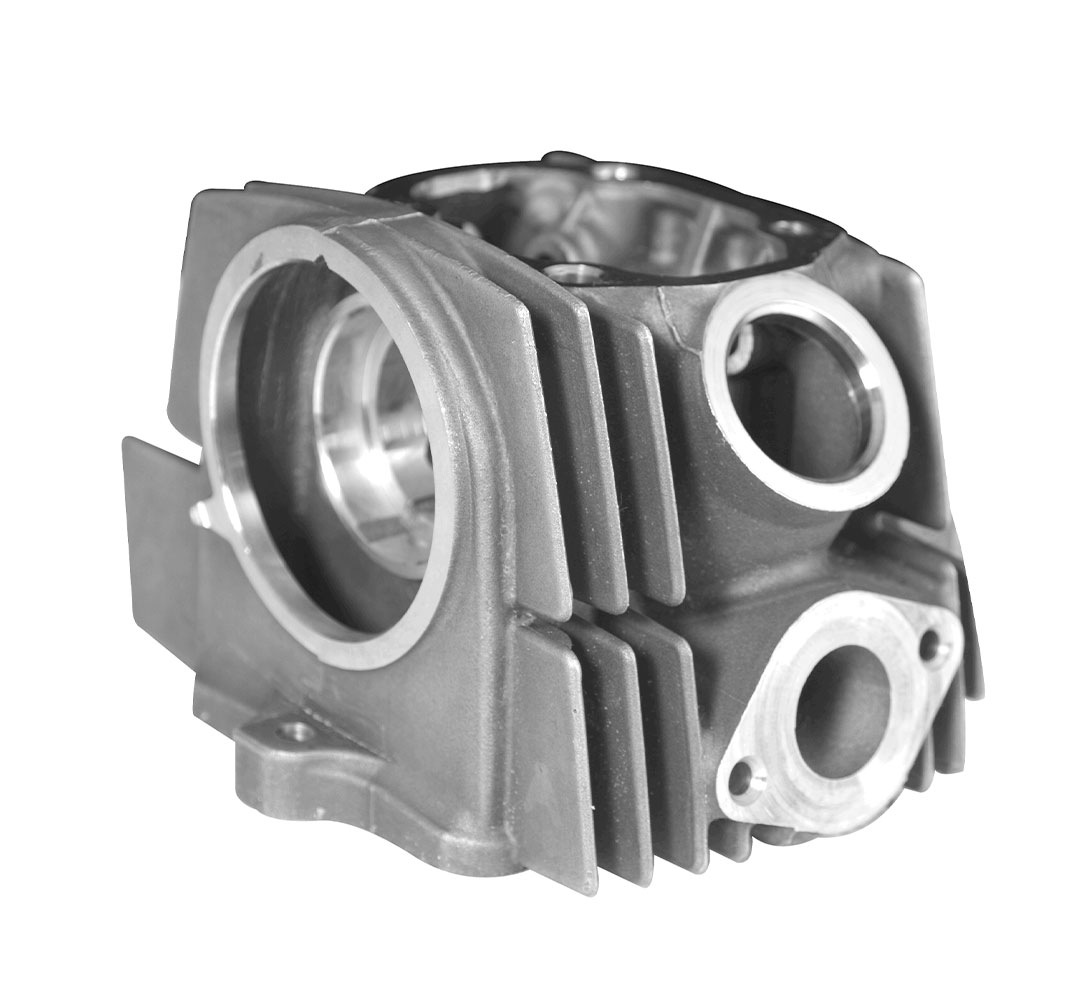

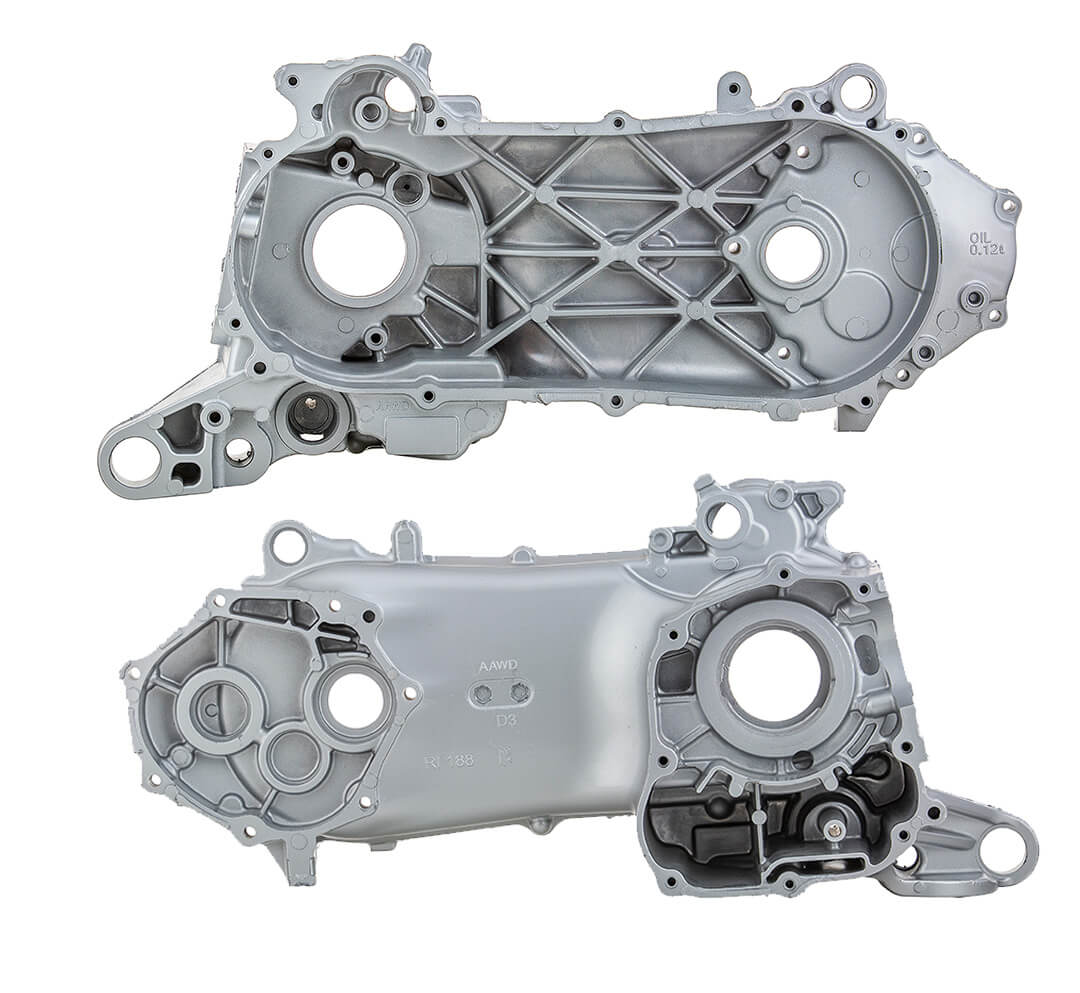

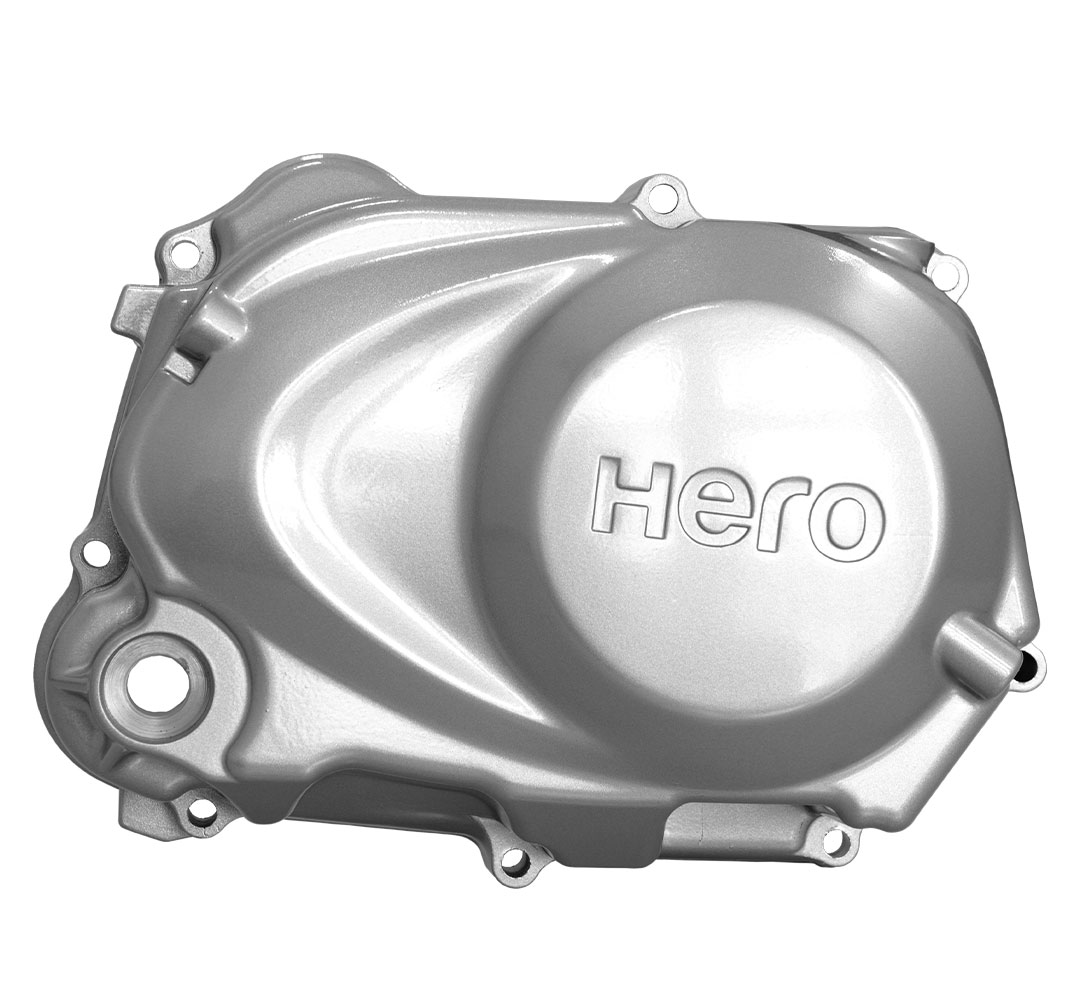

Rockman Industries has been into Aluminium Die Casting since the last two decades andis one of the few manufacturers equipped to follow the three types of die casting processes. Quality management, safety protocols and focus on environmental sustainability is the core of our manufacturing.

The outcome

- High quality, complex die cast components catering to two-wheelers, four-wheelers, and other automotive/non-automotive parts.

- Total employee involvement under the common platforms of TPM, GreenCo, quality circle, Kaizen, 5S, etc.

Engineering & Designs

Project Management

Project management serves an important goal in delivering the product at the right time and location. The key to customer delight is the timely execution of projects.

Rockman manufactures all in-house tools and has expertise in designing precision tools.

The Cross-Functional Team takes care of Project Management. The process takes place by defining the project goals & targets. Later it is completed at the time of final PSW Submission. Close interaction is maintained with the customer during the project development.

Process Development ensures timely identification and deployment of all the necessary resources. Project deployment is processed in terms of inspection, manpower, utilities etc. The process ensures smooth development, trial, inspection and submission of PPAP as per as timelines.

Tool Design & development

- In house centralised die design and development center in Bawal

- Producing 300+ dies/ year at Ludhiana & Haridwar facilities

- Capability to produce tools upto a weight of 5 tonnes

- High precision CNC, EDM, wire cut and high speed machines for machining of tool and dies

- Spotting press for die matching

- End of life drawing and document management done through dedicated windchill based PLM system